About

- Description

-

3C Dual-Adhesive Heat Shrinkable Wraparound Sleeve

Viscoelastic-mastic adhesive composite configuration coating for field girth weld joint

3C Heat Shrinkable Wraparound Sleeve

(Viscoelastic-Mastic Composite Configuration Coating Sleeve,3CS),is the latest product specially designed and developed by Cheray Polymer Co., aim at pipeline field joint corrosion protection technology trend and client actual requirement. It completely solves various application defect of common heat shrinkable wraparound sleeve, such as complicated installation technological requirements, longer installation time, unstable manual installation quality and unsatisfied corrosion protection long term performance. 3CS has excellent competitive advantage as follow:

installation technological is simple and quick; easy learn and operate; much save construction and maintenance cost; excellent corrosion protection long term performance. It is the perfect solution of field joint corrosion protection.

3C Heat shrinkable wraparound sleeve is compatible to girth weld field joint coatings such PE, PP, FBE and PU, also for pipe bend, pipe elbow, fitting and coating repairing.

Configuration:

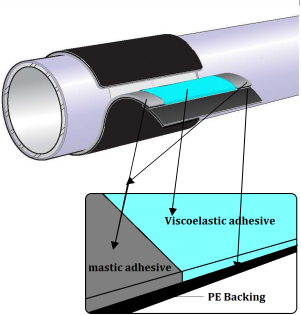

3C Dual-Adhesive Heat Shrinkable Wraparound Sleeve is composited adhesive configuration with 2 layers:

Layer 1:Viscoelastic adhesive and mastic adhesive composite configuration. Viscoelastic adhesive coated on the central part of sleeve, mastic adhesive coated on the two side parts like a belt along the sleeve radial direction, two type of adhesive seamless connect.

Layer 2:Radiation cross-linked high density polyethylene.

Installation feature:

a.Steel pipeline surface preparation just meet ST2.0~3.0,get rid of humidity absorbed water on steel surface is enough;

b.No need coat epoxy primer;

c.Closure patch is pre-installed, save time;

d.Installation process is same with common heat shrinkable sleeve, post heating is not necessary after shrunk;

e.Installation can be done under ambient temperature -40℃.

Benefit:

Benefit:

a.Simple process, Very easy application;

b.Saving application time, quick installation;

c.Long term and high performance corrosion protection;

d.Be suitable for multifarious coating system.

Shelf life:

2 years, under correct storage condition

●To ensure maximum performance, store CHERAY POLYMER products in a dry, ventilated area.

●Keep products sealed in original cartons and avoid exposure to direct sunlight, rain, snow, dust or other adverse environmental elements.

●Avoid prolonged storage at temperatures above 40°C or below -20°C.

●Product installation should be done in accordance with local health and safety regulations.